Abstract

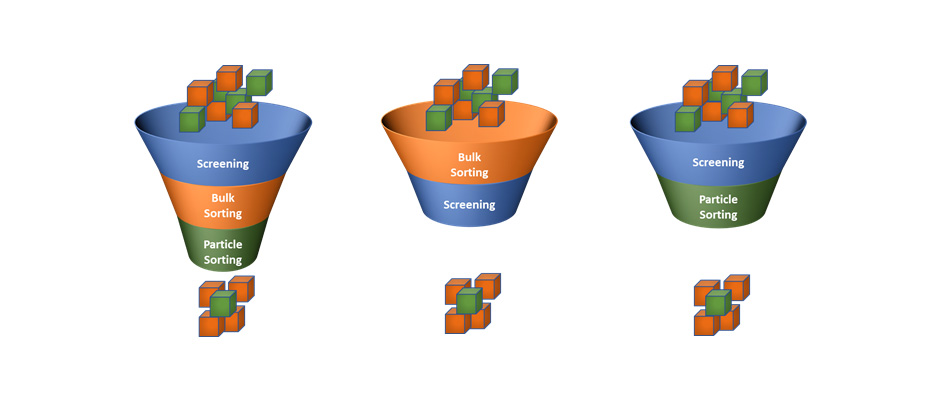

Common challenges for metallurgical testing are to gather samples representative of the orebody and to conduct testing in a cost-effective manner; this is especially true for pre-concentration evaluations. The authors have developed processes that answer these challenges, including new lab protocols that can be applied across a range of projects, particularly those considering particle-based ore sorting.

Heterogeneity is assessed from exploration drill hole data to determine waste and ore distributions in both ore and marginal waste zones. Drill core intervals are targeted for sampling as being representative of these distributions, as well as ore types. These samples are commonly 50 kg of half core – similar to current comminution test requirements as part of a metallurgical testwork program.

Samples are sent to an independent laboratory for assay by size testing as well as sample preparation for mineral sensing testing. Presently, mineral sensor testing samples are sent to specialty research centres or particle sorting equipment suppliers. The new protocol adopts a more cost-effective approach than the current rock by rock, sensor testing which incurs considerable assay costs.

Authors

Bob McCarthy | Principal Mining Engineer | SRK Canada

Dr. Adrian Dance | Principal Metallurgist | SRK Canada