The development of resource-stage diamond projects is materially constrained by the time and cost involved in bulk sampling (or trial mining) campaigns that serve to demonstrate the (macro)diamond grade of the deposit. Comparatively inexpensive assay data for (micro)diamonds may also be used to estimate (macro)diamond grade, by way of geostatistical extrapolation or modelling of diamond size frequency distributions. Current industry practices dictate that the relevant micro/macro diamond size frequency relationship(s) be established on a domain-by-domain basis, and therefore are subject to geological and related sampling constraints pertinent to individual deposits.

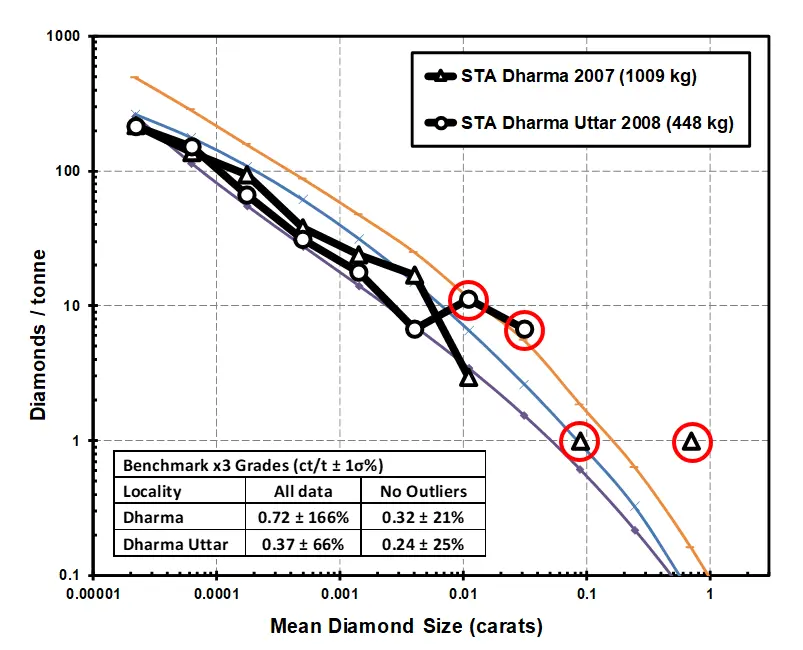

Geoscientists at SRK (Canada) Inc. have completed an in-depth review of publicly available technical disclosure related to micro/macrodiamond sampling campaigns completed since early-2004 across a large number of resource-stage and mine-stage diamond projects. Careful screening of this public domain data set provides thirty separate diamond size frequency distributions that serve to benchmark real-world micro/macro diamond relationships for proven in-situ (macro)diamond grades ranging from 0.04 to 10.2 carats per tonne. Microdiamond assay results from pre-resource and resource-level diamond projects can now be used to estimate macrodiamond grade, based on the real-world benchmarks established by SRK. The grade calculation approach adopted by SRK (see Figure 1):

- always incorporates data for three (or more) appropriate benchmarks

- provides first-order measures of precision (at ±1σ, i.e. 1 standard deviation). SRK actively uses the measured precision to objectively assess the impact of outlier data, a pernicious and common feature of microdiamond assay results

- is not underpinned by statistical models and so makes no assumptions about the nature of the underlying diamond size frequency distribution (e.g. log-normal, log-Laplace, Burr, log-hyperbolic and similar distributions)

Figure 1: Log-log scale “grade-size” plot illustrating microdiamond assay results (in black) for drill-core samples of two kimberlites in the MacKenzie region, NWT, Canada (per Sanatana Diamonds news releases of 20 December 2007 and 15 July 2008). The tabulated macrodiamond grades were estimated with reference to three appropriate benchmarks (purple, blue and orange colors). Objective elimination of outlier microdiamond data (red circles) demonstrably improves precision, leading to final “best-fit” grade estimates of 0.32 and 0.24 ct/t, as tabulated. This example illustrates the impact of a positive bias effect commonly encountered in microdiamond assay results. All grade estimates are stated in-situ at +1.18 mm square-mesh sieve bottom cut-off, and with ± 1σ% relative precision.