Preferential grade-by-size deportment is the tendency for metal content to increase in the fines fraction of mill feed. That is, following blasting and primary crushing the fine particles will be much higher in grade than the coarse particles.

This characteristic is important to identify for each recognised ore type as coarse particles consume a higher proportion of energy in crushing and grinding. Eliminating the coarse fraction would lead to higher mill throughput – particularly for semi-autogenous grinding (SAG) mills. In fact, the coarse pebbles or scats exiting a SAG mill are an indication of this discrepancy in energy requirements. The question is: why are the pebbles returned to the SAG mill if they’ve proven themselves to be more competent?

SRK is working with clients to assess whether coarse beneficiation or pebble rejection is an opportunity to not only increase mill feed grade but increase throughput – using the existing grinding circuit. Coarse beneficiation can be assessed at both the drillcore stage (even on drill cuttings) as well as during operation.

In the case of gold operations, the lower grade, coarse material is often more suitable for lower cost processing methods like heap leaching.

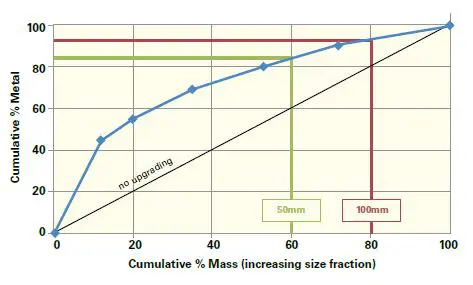

Consider the diagram below which plots the cumulative metal content versus the cumulative mass of material, with increasing size. If each size fraction had the same metal content, then no upgrading line would occur. For the ore type shown in blue, 85% of the metal is contained in 60% of the mass (up to 50mm) and 94% of the metal is contained in 80% of the mass (up to 100mm). Therefore, screening at 100mm would eliminate the coarse, competent component of the feed but retain 94% of the metal. For example, if the mill feed grade was 1.0g/t gold, then the finer, easier to process material would be upgraded to 1.18g/t gold. (Screening at 50mm would upgrade the feed to 1.42g/t gold.)

As an alternative to investing capital into plant expansions – why not consider generating more metal per day at the same plant capacity? Ultimately, metal per day (i.e. revenue) and not throughput or recovery is the real measure of processing plant performance.

As shown in the example, coarse beneficiation offers an opportunity to significantly upgrade mill feed – which can be used to increase revenue or lower the cut-off grade. For projects facing long haulage distances from remote deposits, it can turn such a potentially marginal project into an economic one.