Technology has now reached a point where vast amounts of data can be collected and communicated in real time to allow companies to understand what is really happening in their mines; however, “Big Data” can be overwhelming and can obscure the important information which allow decisions to be made in time to have a positive impact on performance.

At SRK Consulting we understand the dynamics of mining: the variability of the deposit, the practical constraints which prevent ideal solutions from being implemented, the challenges of working in remote locations, the factors which really drive costs, etc.

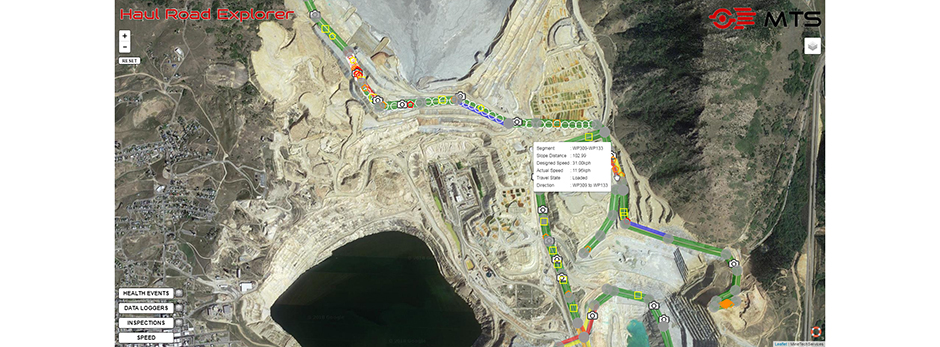

For example, we have teamed up with mining technology specialists Mine Tech Services (MTS) to help mining companies identify and target inefficiencies in their open pit operations. MTS’s Haul Road Explorer software displays operational mine data in a much more visually intuitive way; this coupled with our in-depth mining knowledge helps operations manage the areas which matter most.

For example, we recently visited a mine in North America where they had a world class fleet management system and on-board monitoring in place who wished to understand what further opportunities existed to improve efficiency. Our technology partners, MTS, had provided the mine with their Haul Road Explorer software to help them visualise where the trucks drove slower than they should, where the road conditions caused excessive chassis racking, and what the truck health statistics were at these key areas. We helped the mine understand “where the money is” and structured an improvement programme which focused on delivering the most value.

Specifically, we targeted:

· Reducing the cycle time by eliminating the causes of actual truck speed being less than optimal, by improving, for example, visibility at key bends and intersections or areas where there was excessive racking.

· Reducing excessive racking and potential tyre damage by fixing potholes quicker. This was achieved by creating a view for the shift supervisor to see where each truck “dropped flags” whenever there were excessive racking clusters. The supervisor could then examine the site on their initial pit visit and decide what road maintenance was required. Fixing potholes sooner results in truck drivers being able to drive more comfortably at faster speeds and increase productivity.

· Identifying what detailed information could be collected from the equipment health data to support changes in policy: had trucks ever had to brake suddenly at Y-shaped junctions? Had brakes ever overheated when travelling downhill if a certain gear was selected? Supporting data could then be captured and filed to support the policy change, giving managers the confidence to modify policies.

In each case, the potential gain was quantified, allowing cost versus benefit decisions to be made and corrective work to be validated.