The Chuquicamata underground mine in the Atacama Desert in northern Chile is one of the largest planned mining projects in the world to use block caving with macro-blocks option to mine copper ore. CODELCO is currently finishing the detailed engineering stage and constructing the main infrastructure for the project. The underground mine is expected to begin operations in 2020, with a seven-year ramp-up period and a nominal production of 140,000 tonnes per day.

The rock mechanics team of SRK Chile has provided technical support to the Chuquicamata underground project for the last eight years, including the prefeasibility, value, feasibility, liaison, and detailed engineering stages.

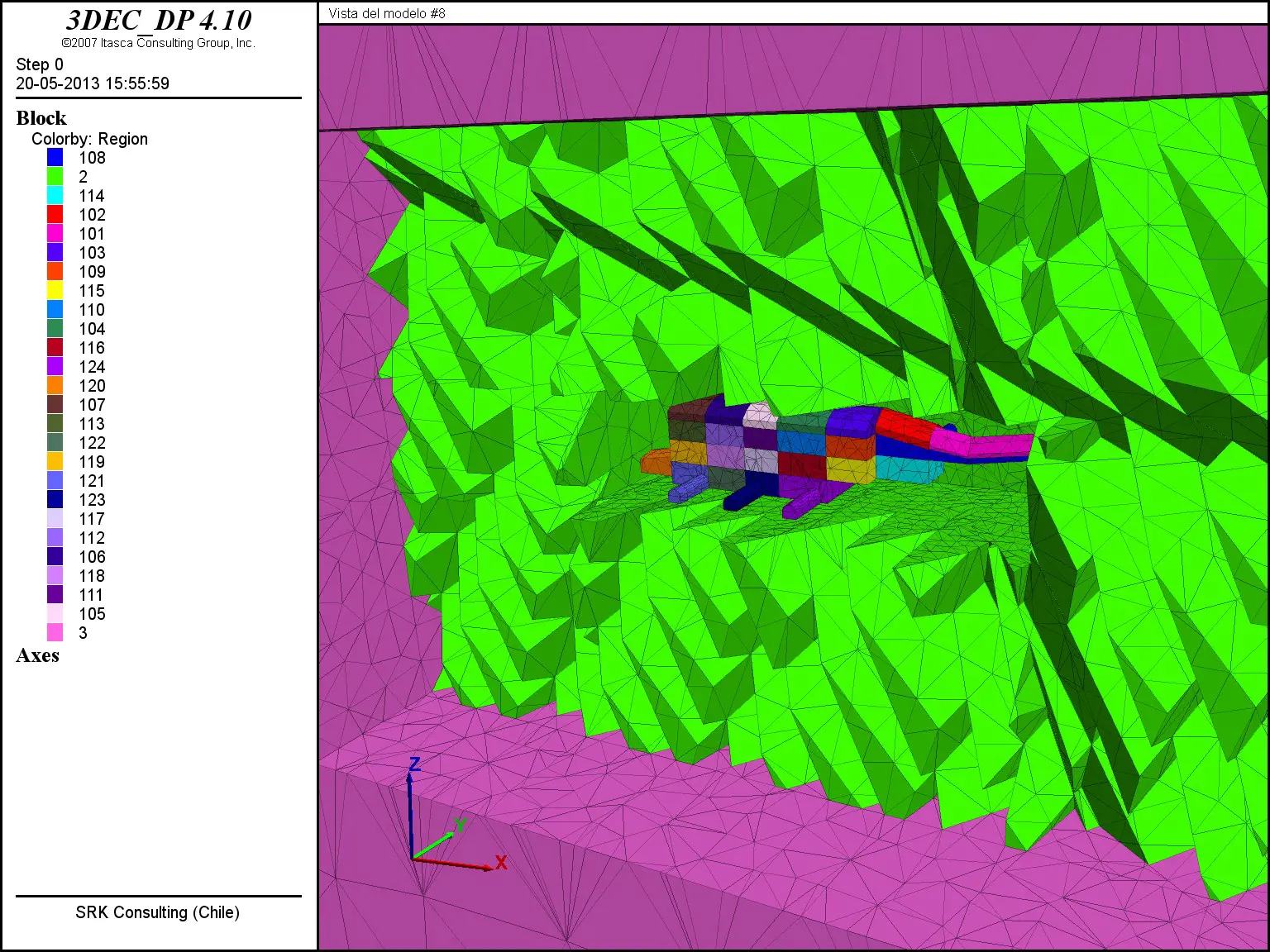

One important aspect was to independently manage each macro-block in the geomechanical assessment to estimate magnitude and extension of the abutment stresses and tensile zones on the macro-block pillars during the different construction phases in macro-block preparation and during the ore column extraction involved in the macro-block operation. This phase depended on complex tridimensional geometry and the interaction of different cavities; so, a tridimensional analysis was required to consider the mining sequence (Figure right).

As part of this study, empirical methods, confinement-convergence analytical models, and 2D and 3D continuum and discontinuum models were developed and applied to evaluate the influence of the stresses and existing geological features (e.g. the presence of two major shear zones, the West Fault, and different lithological units) on the mechanical response of the excavation.

SRK Chile has worked on a wide range of topics in the project, including the geomechanical design at the undercutting level, extraction level and haulage level, the macro-sequence definition, rib pillar and macro-block pillar stability, and the stability and support design of crusher chambers, transfer caverns and several large excavations. Tasks developed range from data collection and interpretation of geotechnical data to the design of underground excavations including more than 50 complex 3D continuum and discontinuum numerical models. To date, the work SRK carried out for the Chuquicamata underground project is summarised in more than 45 technical reports and 110 construction drawings.

Pictured above: Tridimensional numerical model for the Macro-block option; red-excavations, yellow-broken material, white-constructions (before excavations), green-West Fault zone (In situ rock mass has been purposely hidden) (i.e. Hormazabal et al., 2010).