Vast inventories of leach solutions unsuitable for direct discharge to the environment are among the legacies of heap leach operations at closure. The final rinsing and subsequent draindown is a complex technical problem often involving significant cost to the operators. To compound the problem, leachate inventory at closure often exceeds the holding capacity of existing ponds.

The active management phase at closure typically consists of recirculating leach solution to a portion of the heap leach and/or water treatment and discharge, followed by longer-term passive management (without pumping) leveraging evapo-transpiration to continue reducing inventory. Managing the leach solutions represents a significant financial liability. The duration of active management should therefore be carefully planned both technically and financially. SRK has developed a method by which draindown rates and cumulative volumes can be predicted at a daily time scale, enabling the rapid development and comparison of options and scenarios, leading to improved planning.

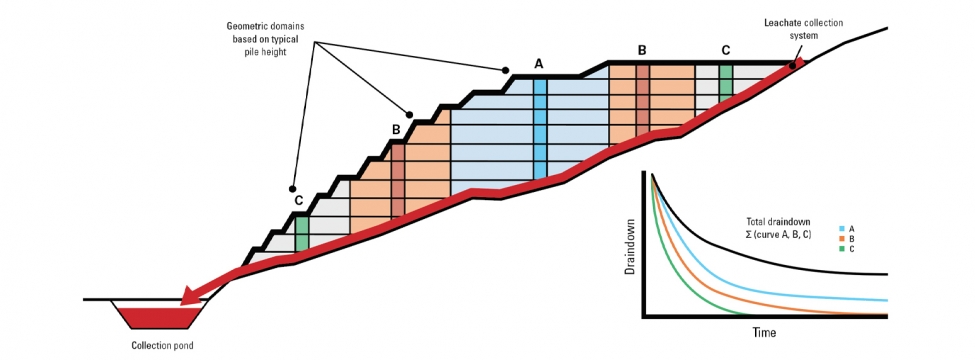

SRK has modelled unsaturated flow through the pile, coupled with analytical modelling of leachate inventory, to predict the time required to achieve passive water management. First, the heap leach pile is discretised into geometric domains, grouping areas based on similar height and/or similar hydraulic properties. Next, the unit draindown rate is determined for each domain through a rigorous finite element numerical model based on the physical and hydraulic properties of the leach material. Finally, the unit draindown curves are applied to the representative footprint of each geometric domain and assembled into an analytical model to compute the expected volume of draindown from each domain.

An example of this modelling approach is provided at a mining project located in a high-altitude arid and cold environment, where the regulatory agencies imposed a zero-discharge condition on the heap leach facility at closure. Elimination of the excess inventory was achieved through evaporation by recirculating the leach solution to select areas of the pile, coupled with evaporation from the storage ponds. Draindown volumes were computed in a daily time step and compared to the remaining inventory.

This approach solved one major challenge of draindown complexity, where portions of the pile are in distinctly different stages of draindown according to when they were last irrigated. Recirculation to some areas and not others also had a significant effect on the time required to reduce flow rates to an acceptable level.

Once the inventory was sufficiently reduced and the draindown rates diminished below the evaporation rate from the storage ponds, the pumps were turned off. SRK’s model was used to determine the likely duration of active management and at what point the system could move to long-term passive management. Several alternatives were assessed, providing crucial data for the cost-benefit analysis of the available options.