During the pit design process, it is important to do the slope stability assessment for the most representative pit slopes and understand if the proposed pit design complies with the acceptance criteria. However, even if the assessment shows that complies, it is advisable to consider that the pit implementation plays a significant role in the slope’s stability. Although the industry dictates that any slope in a pit needs to be investigated before the implementation, it is important to understands that there are still normal situations that can trigger massive instabilities. The potential for unexpected massive slope instability could be decreased using the geotechnical reconciliation processes. For that, short and long-term slope monitoring plans should be implemented at the early stages of a project.

Monitoring programs should provide information on wall displacement, direction of the wall movements, development of deep failures, anticipate if the potential faults activated due to the mining progress, measure blasting vibrations, determine the efficiency of the pore pressure reduction, study deep displacements associated to faults and rock contacts.

It is significant to determine the trigger of a long-term monitoring to have a guidance on critical displacement and velocity by estimating the ultimate displacement of each rock mass at the time where the rock failure should be initiated. Based on the rock mass strength (sRM) and the rock mass static Elastic Modulus (ERM), it is calculated the ultimate displacement before the failure for each rock mass.

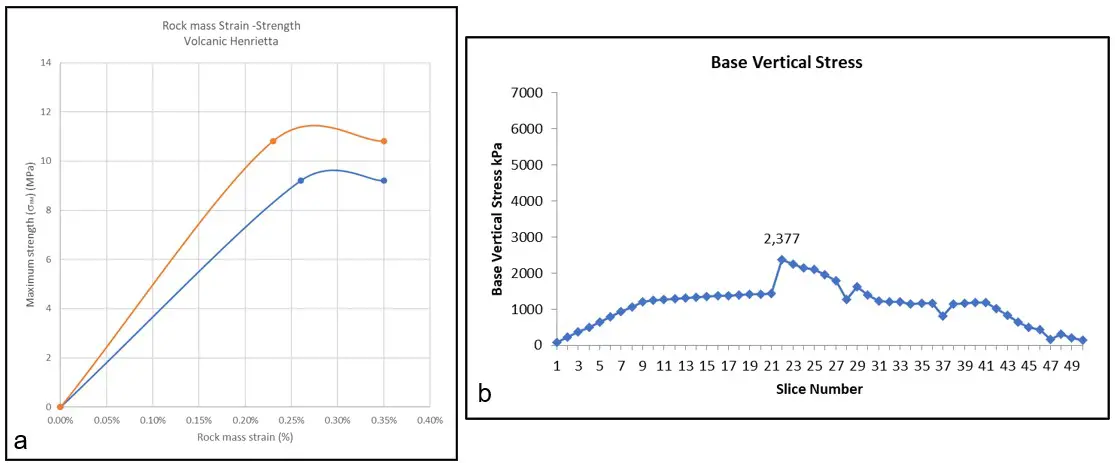

Figure 1-a shows an example of a rock mass strain-stress curve for two damage factors (D); D equals 0.7 for heavily damaged material and D equals 0.5 for medium wall's damage. Depending on the induced stresses, the rock mass will deform until reaching the defined displacement trigger.

In other words, the potential for instability will depend on the slope geometry and the vertical mining progress. For a large open pit, for example, the induced stress needs to be calculated based on the mining plan. To determine the induced stresses and the expected strain of the rock mass, numerical modeling should be the preferred option.

Figure 1-b shows the induced normal stress on the failure surface for a stability model, as an example. The obtained maximum induced normal stress is then used for determining the expected maximum rock mass strain and determine the potential for block mobilizations. In the example shown herein, the failure surface is fully located in the lithology from Figure 1-a.

In this case, the induced normal stress reaches approximately 2,500 kPa, which should induce 0.10% of strain. Given the critical ultimate rock mass strain reach up to 0.25% it is unlikely to initiate a slide. A differential change in velocity of 0.15% (0.25%-0.10%) should be an indication of a potential for a rock mass failure.

When the rock mass strength cannot be estimated, is transcendent determines the ranges of critical displacements and velocities. They must be considered as initial values and need to be calibrated based on monitoring analysis.

Then, it is possible to determine three stages of displacement, which could have different naming and convention to define the level of alarm depending on each company: (a) Warning Stage, (b) Danger Stage, and (c) Ultimate Stage.

Figure 1: (a) Rock Mass Strain-Stress; (b) Induced Normal Stress