As the mining industry deals with restrictions on how people move around the world, the way we work needs to adapt to keep operations safe and where possible productive. Many mining operations rely heavily on employees rotating on and off site. In response to COVID-19, operations have limited the number of people on site to follow social distancing guidance, in some cases with activities restricted to care and maintenance.

Available and innovative technology is now playing an increasing role, and new benefits are being realised. SRK has been working with mining companies to provide expert services using remote technology for inspections, audits, training, and data collection. SRK has developed tools for remote sensing and field data capture systems that we currently use. Satellite and drone image data are used to identify ‘areas of interest’ that are subsequently visited by site-based teams with survey equipment and high-resolution video cameras. Using regular teleconference meetings, effective lines of communication are built up, which enables data to be reviewed as it is generated and modifications made to the program based upon findings/progress. High-quality photographs (with high pixel density) are used to assess fresh drill core for example, to understand ground conditions as they are encountered and to adjust drilling, sampling and testing regimes or monitoring-installation as required.

Working with SRK’s mining technology partners, Mine Tech Services (MTS), highlights how existing technology already installed on many mine sites can be used to solve a variety of mining operational challenges with data and technology. MTS reports in their blog six prominent operational issues and ways to address how these problems can be solved.

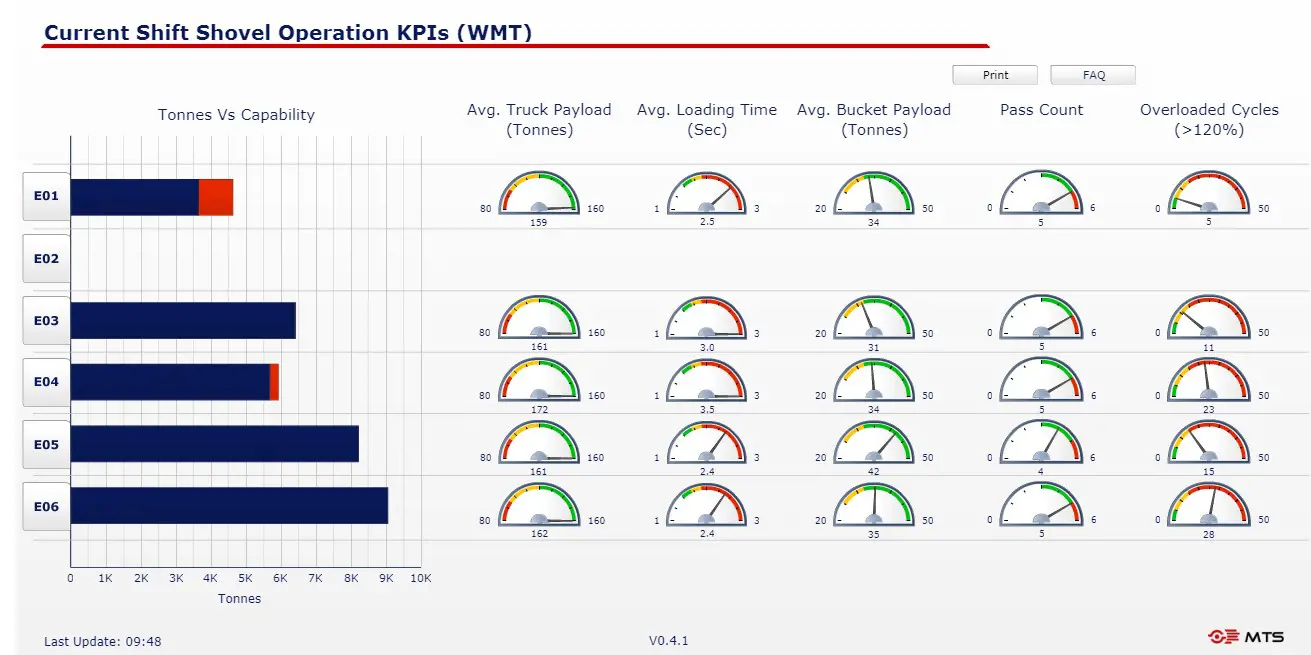

Production & Asset Performance Reporting

Performance dashboards provides an operation with a visual data platform, that presents key performance indicators (KPI) in real time. This solution eliminates manual data collection and visualization, which in the case of many operations would only become available at the end of the shift. This eliminates time lag on up to date information, reduces errors and keeps operations staff, engineers and management informed, wherever they are in the world.

Actively Manage the Execution of the Mine Plan

A mining operation’s compliance to plan maintains flexibility to react to unplanned events and supports efficient operations. To best communicate and help execute the mine plan, MTS suggests using technology that integrates the mine plan with the Fleet Management System (FMS). Communication can be automated, facilitating review at shift change, for example. Production dashboards can be used to compare actuals vs plan in real time. This provides transparency between the engineering and operation departments, allow timely decisions to be made during the shift, and with accurate data capture to improve reconciliation of the plan over time.

Shift Performance and Handover

To streamline shift handover and review shift performance, an app that captures information in standardised format can be prepared. This would be automatically merged with production and asset performance data and reported at the end of each shift, greatly improving the communication to the management team and oncoming crew.

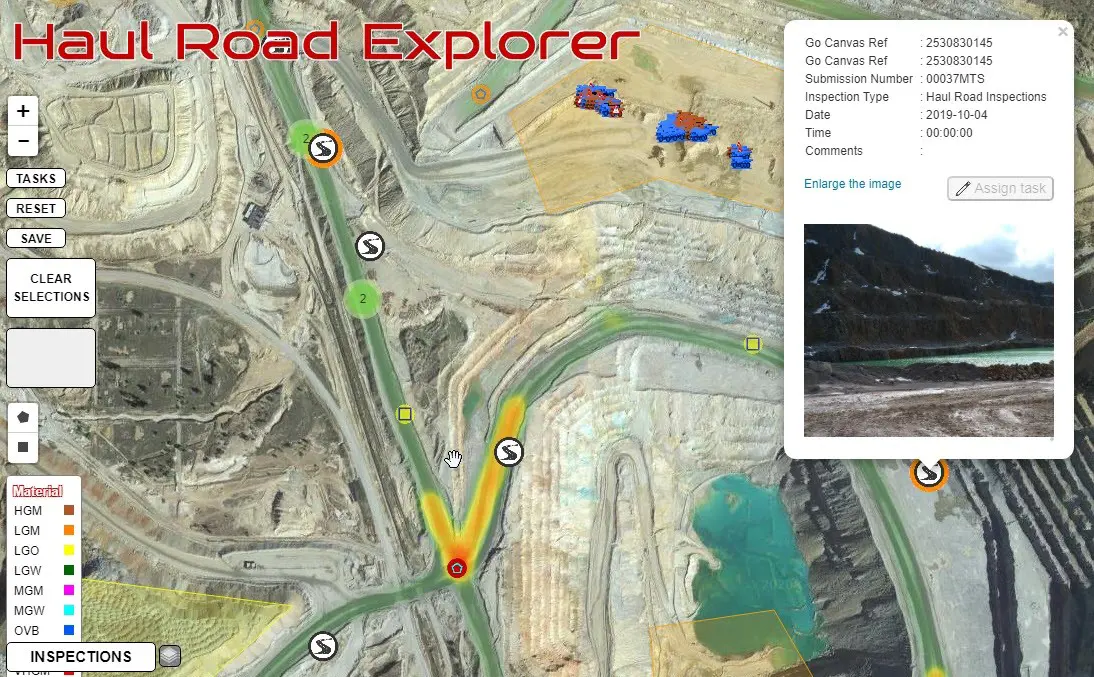

Haul Road Management

Haul road design and maintenance, correct asset operation, and maintenance practices are essential for excellent fleet productivity. When working remotely or with small crews, haul road management without technology is difficult. Software such as Haul Road Explorer (HRE) developed by MTS, can combine multiple data sources into a geospatial model and perform root cause and gap analyses. This provides pre-calculated opportunities for haul road corrective actions, such as predicting which sections of road require maintenance. This can help shift planning and operations get most benefit from their limited resources.

Relocate Roles Offsite

Many people now work from home very successfully: some roles and functions normally based on site could, with the right support, continue to operate offsite for longer periods or even permanently. Robust communication infrastructure is required. Support with relevant data collection and presentation of information could assist future operations reduce the impacts of personnel travelling to and working on remote sites, and possibly lower associated costs.

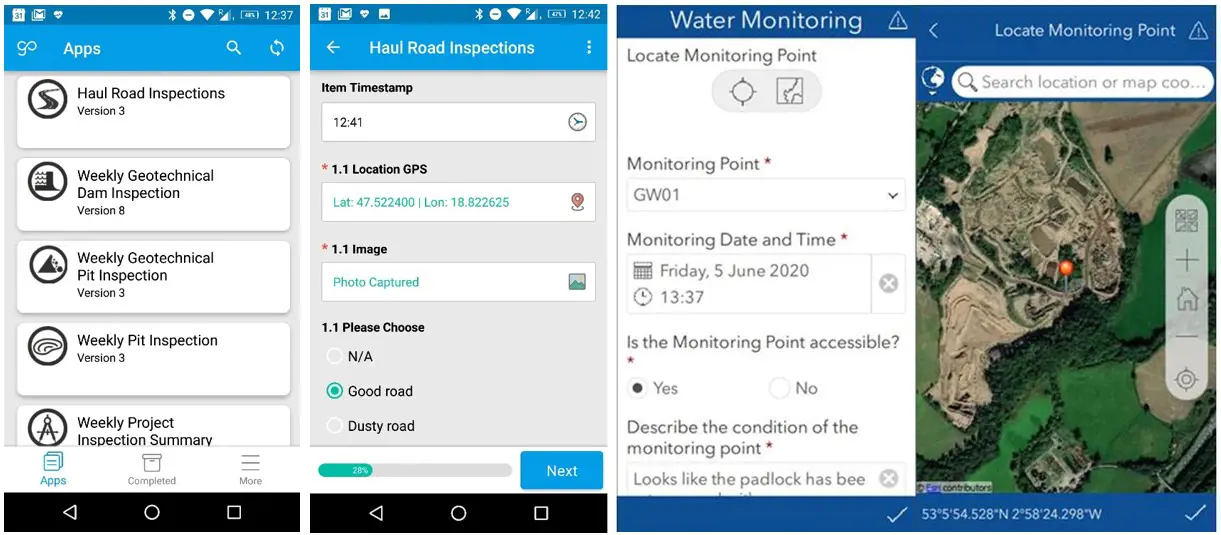

Paperless Inspections

Many inspections conducted on a mine site are completed on paper and later physically filed or entered into a database or spreadsheet. This often results in poor data quality; missing information and inflexible data structures can lead to weak data analysis. MTS and SRK have developed cell phone and tablet-based inspection apps using commercial software to easily capture the same information with enhanced features such as GPS coordinates, measurements and photos. Data is automatically stored in a database, securing the information and enabling rapid analysis of historical inspections and performance trends.

SRK and its partner MTS will continue to work with our clients to keep operations safe and, where possible, productive. Our expert services provided via remote technology and new insights from data collection and visualisation technologies are bringing new benefits that will help companies manage their operations and projects through the current crisis and shape the way we work into the future.