With an ever-present need to control costs, the management and closure planning of tailings storage facilities (TSFs), already perceived by many as a heavy cost burden, are key areas targeted for savings.

Closing a TSF can be deemed successful if it is geotechnically stable, geochemically benign with a suitable cover in place, and the area fit for the agreed post-mining land use. The concept of ‘deposition for closure’ using thickened tailings and central discharge is becoming increasingly attractive due to budget pressures and more stringent closure requirements. Thickening and dewatering technology in general is continually being developed and improved, and there are key learnings from mine sites across the globe that adopted this strategy – advantages as well as challenges.

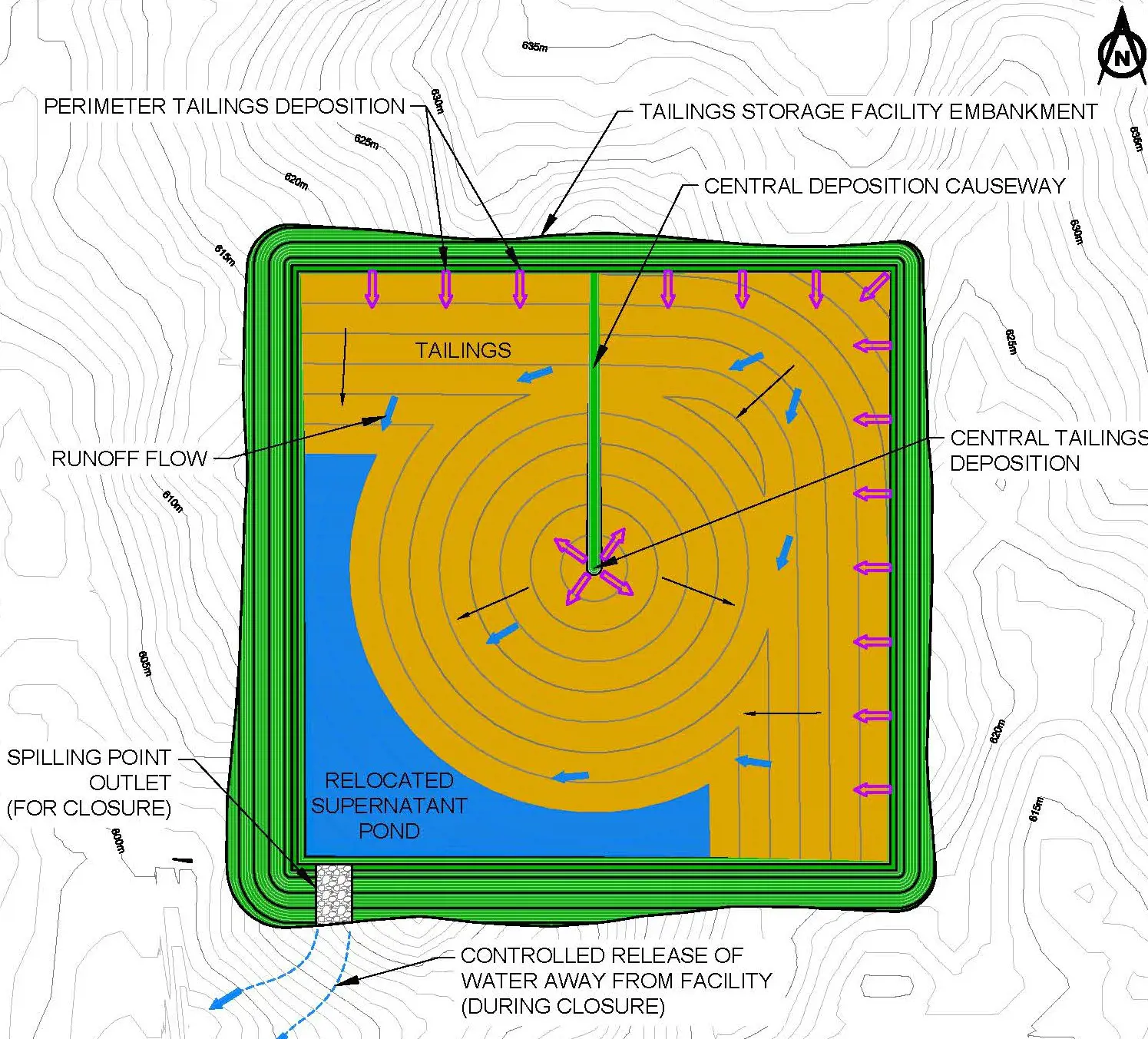

When closing a conventional slurry TSF, a major challenge is the long-term management of the central surface pond. The tailings typically take a long time to consolidate, and creating a suitable final closure landform shape can often require substantial earthworks and quantities of borrow fill material. Implementing modifications to introduce thickened tailings and a central deposition strategy at an existing TSF towards the end of operations can help create a final convex, water-shedding surface, which can be complemented with a suitable cover layer at the end of the life of the facility. This early change allows passive management of excess water as part of closure preparations by directing the controlled flow of runoff away from the TSF by way of a spilling point into natural drainage downstream.

The use of thickened tailings can result in a shorter delay between the end of operations and the start of cover placement, which means less time and cost expended in overall closure of the mine. In addition, the strategic placement of thickened tailings can increase the storage capacity in the TSF, which could potentially reduce further footprint impact.

Before implementing a change to thickened tailings deposition, the TSF requires a thorough evaluation to ensure that the facility can safely and economically transition to a central discharge system. The slurry’s geotechnical, geochemical and rheological characteristics must be investigated, and geotechnical stability of the embankment slopes should be analysed to ensure they are not compromised by water ponding against them. Additionally, the impact of thickened tailings on the beach slope must be assessed, along with the liquefaction potential. The potential for differential settlement to occur between the existing conventional tailings and the new denser thickened tailings should be considered in the deposition plan.

A deposition for closure strategy applied to an existing project raises site-specific issues and challenges. These include considering the cost required for the necessary infrastructure – including thickeners, disposal pipelines and a causeway to the central deposition area. Adjusting the disposal methods to include central thickened tailings discharge may be more operationally intense, requiring specific training and guidance for operational staff.

While there are numerous potential advantages, including overall reductions in both cost and time expended in implementing a facility’s closure, it is critical to have a thorough understanding of the potential trade-offs before implementing the new strategy.