Quantifying Tailings Dam Risks was a one-hour session that took place on June 11, 2020, at Mining Insurance and Risk Association (MIRA). The talk presented a comprehensive approach to address how to quantify and prioritize tailings dam risks, especially in the context of large dam inventories.

In this blogpost, we summarize the Q&A session that followed the talk, classified by theme.

At the end, we present a synthesis before some closing remarks.

Understanding Geology and Background

Q1: How does site investigation influence the risk assessment of dams?

A1: Site investigation, preliminary understanding of site’s geology, climate, hydraulics and extreme events are fundamental to future acceptable performance of a dam. Many failed dams had inceptual defects that showed up later, when a certain volume/height was reached. Many of those defects could have been avoided with a sustainable additional effort at investigation level, such as deeper boreholes.

Q2: What is the weight of the site investigation as a Key Performance Indicator (KPI)?

A2: Site investigation is not a single KPI. Many KPIs contribute to site investigation, so, it is difficult to give a specific number: the nature and details of the site investigation determine that “weight.”

Factors of Safety and Failure Rate of Dams, Likelihood

Q3: Does increasing the dam capacity, years after initial construction, reduce the FoS?

A3: There is no a priori answer to this question. One must perform analyses of the dam “as is” to reply.

Q4: What is the average failure rate of all tailing dams?

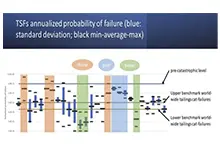

A4: At Riskope, we were the first in the world to evaluate the rate of failure of the worldwide tailings dams portfolio (Oboni & Oboni 2013). We ended up selecting two decades (around 1979, i.e. 1974−1984, and around 1999) as benchmarks for our ORE2_Tailings™ benchmarking exercises.

Q5: Determining probability of failure for investigation, design, construction, and operations and maintenance components is key in determining the aggregated probability of failure for the tailings management system. How were these probabilities of failure determined?

A5: Riskope uses their proprietary methodology to analyze the appropriate KPIs, combine causalities including ancillary water management facilities and yield the probability of failure of a dam. The probability transparently includes the uncertainties on the various KPIs.

Q6: How was the model back-tested against actual failures and what type of correlation to probability failure/year was observed?

A6: ORE2_Tailings is the result of over two decades of applied research and development. We have deployed it on tailings dams in the most diverse climate and structural conditions. We benchmark each result and we have evaluated several cases of catastrophic failures to see how the methodology responds to poor dam conditions.

Future of Tailings Storage Facilities (TSFs)

Q7: Do you foresee an increase or decrease of probability of failure of TSFs, an increase/decrease of consequences of failure of TSFs or both?

A7: This question opens a Pandora’s box. Let me try to answer in a concise and simplified manner. Modern dams, which are well-studied, designed, built, managed and monitored, have a probability of failure lower than the worldwide portfolio. That probability of failure becomes higher if the dams are neglected, unrepaired, or poorly monitored. The consequences of failure depend on the topography, land-use downstream, existence of a water body or water course downstream and many other factors. Thus, again, there is no possible serious answer if there is no risk analysis. Anyone claiming that larger dams are riskier, for example, is taking a hazardous shortcut that is easy to disprove with facts. Anyone claiming dams should be prioritized by their consequences, or by their probability, is also going down a hazardous path.

Monte Carlo or Other Methods?

Q8: Do you consider some type of Monte Carlo assessment/probabilistic analysis necessary to determine the FoS on the TSFs? And if yes, should regulators request them? Is this a real way of considering geomechanical uncertainties?

A8: Monte Carlo is a tool like any other. One can perform probabilistic analyses using various methods, as a function of available data and level of detail. Considering geomechanical uncertainties in developing the probability of failure is not sufficient and generally leads to overestimating the probability of failure. The issue is so important that we are writing a paper for Tailings and Mine Waste 2020, entitled “The Factor of Safety and Probability of Failure Relationship.” The paper goes back to the mid-1980s, when we published a very technical approach to this relationship. So, to put it in simple words, for us it is a 35-year-old “pain in the neck” issue!

Failure Modes and Causality

Q9: Could you explain a little bit more about failure modes as a design tool?

A9: Failure modes explain how a failure occurs, not why it occurs. We are preparing a piece on this which uses a medical example. For instance, heart failure is a failure mode of the human body, but the prior lifestyle and other pre-existing conditions are the causes of that failure mode.

Applying this reasoning to tailings dams, we can immediately see that concentrating on failure modes may be good for a designer. Designers indeed try to eliminate weaknesses, failure mode by failure mode. However, in a risk assessment, we are interested in seeing how the many possible causalities lead to failure, not so much in how that failure occurs. Incidentally, the latest catastrophic failures forensic analyses have clearly shown that they occurred because of a complex interaction of causes and not because of a single failure mode!

Technology Adoption

Q10: In your opinion, do most mining companies with TSFs use your quantitative analysis methodology to better understand the probability of failure?

A10: We have worked continuously in the mining arena since the mid-1990s, including in tailings systems, entire operations, pits, access roads, railroads, pipelines, water treatment plants and equipment.

We have a number of repeat mining and insurance clients and their number is growing rapidly. That is thanks to ORE2_Tailings and its seamless link to space observation. This link enables us to prioritize portfolios while reducing the need for extensive site visits. This is a particularly interesting feature in these times of pandemic and geopolitical turmoil.

Q11: Will engineers such as KP/SRK/BGC etc. use your modelling in their reports?

A11: We already have large engineering firms as clients and their number is bound to increase. Indeed engineering firms, large insurers or space observation companies wanting to offer a “one-stop shop” service to their clients will derive great advantage from using ORE2_Tailings.

Summary of Q&A Session on Quantifying Tailings Dam Risks at MIRA

The questions were extremely interesting and focused on practical aspects related to the use of ORE2_Tailings. They ranged from the need for information to expected performances of the methodology, as well as its testing and proof. Several questions indicated a need for predictive analyses which are precisely the reason for developing ORE2_Tailings.

Finally, participants asked questions on the spread of use of the methodology. As a result, we shared Riskope is already cooperating with large mining companies, engineering firms, insurers, and space observation companies willing to know more about their portfolios and to offer a “one-stop shop” service to their clients. That is, of course, in addition to mining companies interested in knowing more about their portfolios and performing rational risk-informed decision-making.

Closing Remarks

Numerous participants asked, “What about a next session?”

We are ready to hold future sessions in English, French or Spanish.