Economics and safety of large open pits rely primarily on the stability of the pit slopes. However, many historical operations do not adequately consider geotechnical aspects for pit slope design or for its operational management. As a result, geotechnical risks and opportunities associated with the operations remains unidentified.

SRK India was retained to undertake a geotechnical audit of open pit operations owned by a metal mining entity. The aim of the audit was to review performance

of the pit slopes and to use the audit as a benchmarking tool to compare with international best practices.

SRK considered 25 parameters to evaluate the geotechnical condition of the pit slopes. These included the mine-scale geology, structure, and geotechnical setting;

geotechnical reports that supported pit slope design; Ground Control Management

Plan (GCMP); reviews of pit inspection and slope monitoring practices and associated documentation; performance of surface excavation in hard rock, weak rock, and soil faces; and ramp performance and the role played by an in-house geotechnical team. The audit scope excluded review of waste dump and tailings facilities and also excluded any slope stability analysis.

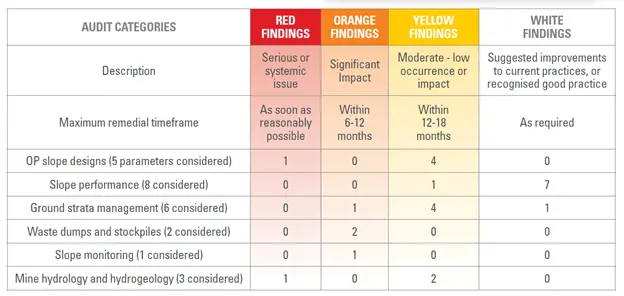

The parameters were divided into four categories (red, orange, yellow and white) based on the risk associated with each parameter. Action points were derived for the parameters and were ranked. A timeframe for the actions was also recommended.

The table below shows an example of an audit summary. The mine design was not based on an appropriate geotechnical study; however, the pit slope parameters were conservative and therefore the pit walls were found to be reasonably stable.

Implementation of the prioritised action points may help pit slope steepening (with adherence to the safety standards) and may thereby improve the economics and safety of the mine.